05.03.2024 | Sustainability

At Daimler Truck we have further progressed on our transformation, although we know we still have a long way ahead of us.

05.03.2024 | Sustainability

At Daimler Truck we have further progressed on our transformation, although we know we still have a long way ahead of us.

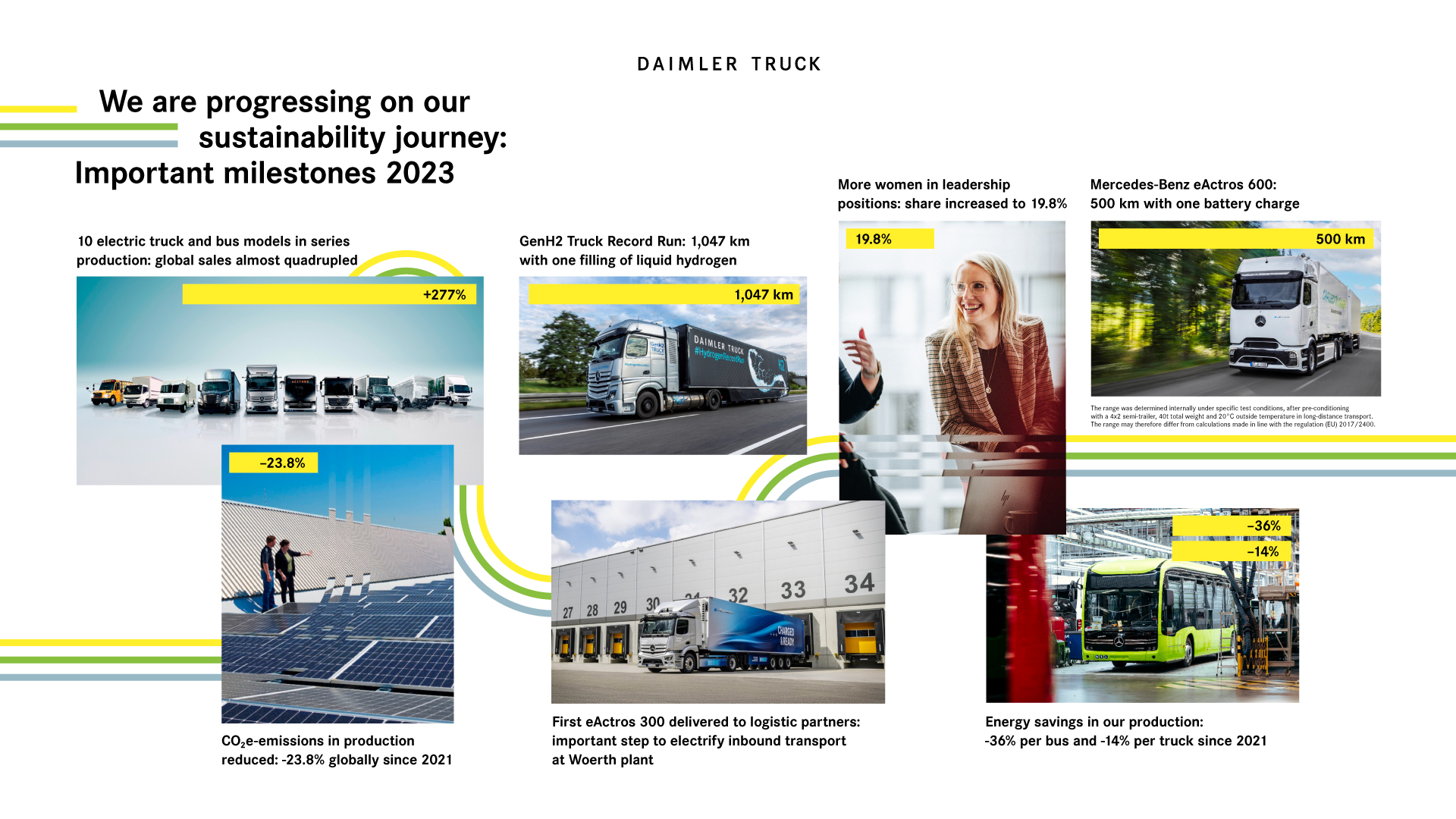

We have 10 electric truck and bus models in series production and have thereby achieved a fourfold increase in sales compared to the previous year.

This corresponds to an increase to 3,443 sold units. We want to continue to increase the sale of electric vehicles. To do so, a vast expansion of the necessary charging infrastructure network will be key. We collaborate with partners in joint ventures such as Milence in Europe, Greenlane in the U.S. and H2Accelerate, to bring forward the expansion of charging infrastructure, both for battery-electric and hydrogen-powered vehicles. We also want to scale the battery cell production for electric commercial vehicles by partnering with Accelera by Cummins and PACCAR in the U.S.

We have developed and publicly presented the eActros 600, a battery-electric long-distance truck with a range of 500 km[1] per battery charge.

Series production is scheduled to start at the end of 2024. The eActros 600 has the potential to save 40% of CO2e-emissions when charged under the current European energy mix[2] – and up to 80% when charged with renewable energy only – compared to an Actros with a diesel engine and covering the entire product life cycle of ten years starting at raw material extraction. This is equivalent to saving 370 or 775 tons of CO2e-emissions respectively. The eActros 600 can therefore equalize its higher CO2e-emissions in production due to the battery within its second or first year of operation in long-distance transport.[3]

Our fuel cell prototype Mercedes-Benz GenH2 Truck drove from Woerth am Rhein to Berlin – with one tank filling of liquid hydrogen and under realistic traffic conditions.

This test drive over 1,047 kilometers has shown how performant this technology can be, especially in flexible and demanding long distance transport conditions. Consequently, we are now taking the next step by building a first customer-trial fleet of Mercedes-Benz GenH2 Trucks. Expected from mid-2024, selected customers will take part in first customer trials to gain initial experience in long-distance transport with fuel-cell trucks.

We have reduced CO2e-emissions from production globally by -23.8% since 2021 and expanded the use of solar energy.

We are continuously working on reducing our CO2e-emissions and resource consumption related to production. In 2023 we have decreased our CO2e-emissions by 23.8% compared to 2021, mainly through the use of renewable energy and energy efficiency measures.

We’re also expanding our onsite energy generation. Already today we have photovoltaics installed across our global sites with a power capacity of 20.6 MWp – compared to the previous year this is an increase of 286% in the number of installed photovoltaic modules. We are able to generate around 25.7 GWh of electricity per year and have thereby achieved a fourfold increase in on-site generated electricity.

We’ve begun the construction of a new logistics site in Halberstadt, Germany, that will run entirely without fossil fuels. It will be heated with electric heat pumps, and the planned installation of photovoltaics on its roof will generate up to 13 GWh renewable electricity – enough to also support other sites in Germany.

We have reduced energy consumption by -36% per bus and by -14% per truck in production since 2021.

We have achieved it through efficiency measures and volume effects from the higher number of vehicles produced, among other things.

Our share of women in leadership positions has increased to 19.8%.

We want to be a good employer and foster a culture of diversity, equity and integration that creates a feeling of belonging across levels and locations. The share of women in leadership levels increased to 19.8% globally. We are on track to reach our ambition of having 25% of women in leadership positions by 2030.

In 2023, we founded the new Diversity, Equity & Inclusion (DEI) Advisory Board, made up of a diverse and international group of people from all business units across eight countries and five continents. The Advisory Board makes decision about the strategy and material topics relating to diversity, equal opportunities and inclusion. It advises the Daimler Truck Board of Management and integrates the topic across all business units.

We want to increase the use of electric trucks in our own supply chain and completely electrify the inbound transport to our biggest production site in Woerth by end of 2026.

2023 we took a decisive step toward this goal: several logistics partners have sourced our battery-electric eActros 300 for use in our inbound transportation and first customer deliveries took already place. From Q1 2024 around 50 daily transports to the factory in Woerth will be performed fully-electric with these vehicles.

We have new innovative safety- and assistance systems in trucks and buses for increased traffic safety.

We have intensely tested our newly developed assistance systems such as Active Brake Assist 6, Active Sideguard Assist 2, Front Guard Assist, Active Drive Assist 3 and Traffic Sign Recognition. These will be gradually implemented in our trucks and buses from 2024 onward and is another important step on our way to accident-free driving in our vehicles.

All further information about our sustainability-related activities in 2023 can be found in our integrated annual report pp. 61-128. General information about sustainability at Daimler Truck can be found on our website.

[1] The range was determined internally under specific test conditions, after pre-conditioning with a 4x2 semi-trailer, 40t total weight and 20°C outside temperature in long-distance transport. The range may therefore differ from calculations made in line with the regulation (EU) 2017/2400.

[2] The CO2 footprint of the eActros 600 is strongly determined by the energy mix used for charging the battery.

[3] Based on a life cycle assessment performed in line with ISO 14040:2006+A1:2020 and ISO 14044:2006 +A1:2017+A2:2020 standards and critically reviewed by internal experts. The results of the life cycle assessment are strongly determined by the data and assumptions used, including the specifications of functional elements and methods. A comparison with other models or vehicles is therefore neither intended nor recommended.