At Daimler Truck, we are fully commited to sustainability not only in the development of new emission-free vehicles, but also in the production of our products. We are aware of this responsibility and are facing up to the challenge. For this reason, we are working to make our production as environmentally friendly as possible and to reduce CO2-emissions and resource consumption.

Green Production

Our ambition

We are continuously working on using the resources in the production more efficient and environmental friendly.

We have realized CO2-neutral* production in Europe on the balance sheet; in the USA, Japan and India we strive for it in 2025 - and globally by 2039.

To drive the transformation of our industry forward quickly, we are working intensively to achieve CO₂-neutrality and decarbonization at our sites around the world.

*among other things through the procurement of CO₂-free electricity from solar, wind and hydropower and through procurement of certificates

Our path

To achieve our ambition and to expand climate protection and resource conservation in production, a few years ago we launched the "Green Production Initiative”. This initiative aims to reduce CO2-emissions, increase the use of renewable energy, improve energy and water efficiency, and reduce waste at our global production sites.

-

CO2-neutral global production

In this context, we are pursuing a four-pronged strategy on our path to CO2-neutral global production:

- Improved energy efficiency

We will steadily cut energy consumption at production sites by around 590 GWh by 2030 (compared to the years 2013 and 2014). - Purchasing of renewable energy

We are focusing on renewable energy in our factories. Here we are continuously evaluating the regional energy markets so that the green power supply can be expanded at all of our locations. Since the beginning of 2022, the majority of our production sites in Europe have been supplied with green electricity from wind turbines, photovoltaic systems, and hydroelectric plants. By 2025, we also aim to supply 100 % green power to all our production sites in the USA, Japan, and India. All other in-house production sites are set to follow by 2030 at the latest. - Company production of renewable energy

In addition to purchasing green electricity, we are continuously driving forward the self-generation of energy at our production sites. Around 7.2 MWp of photovoltaic modules have been installed worldwide, generating around 7.9 GWh of electricity per year (as of the end of 2022). Further photovoltaic systems are planned at numerous locations – including Turkey, South Africa, Mexico, and Japan. - CO2-compensation in transition phase for remaining emissions

We are compensating our currently remaining CO2-emissions with qualified climate protection certificates. At Daimler Truck, we consider compensation to be a means of transitioning to a CO2-free production. At the same time, we are working on further technical means to reduce emissions at the production sites themselves. Our sustainable business strategy aims to avoid emissions in the future as much as possible.

- Improved energy efficiency

-

Water Reduction

We aim to reduce our water use, for example by closing water cycles and making our production processes more water-efficient. In addition, measures are being pursued to decrease the use of drinking water.

In 2022, we conducted a global site-specific water risk assessment ("basin risk") using the WWF Water Risk Filter, increasing data transparency around water stress across all our manufacturing sites. We will use the results to make enterprise-wide as well as local project decisions related to site development, to assist with individual water efficiency projects and water initiatives, and to proactively minimize our risks related to water stress, potential water scarcity, flooding, and water quality.

-

Waste Reduction

Reducing waste is also an essential part of using our resources sparingly. To achieve this, we are working harder to reduce the consumption of raw materials and materials at our sites. We are minimizing waste such as offcuts, sand, filter materials and sludge through new or optimized production processes, and closing off material cycles wherever possible. We are also trying to reduce our packaging materials from parts transport.

In principle, we strive to dispose of our waste primarily through recycling processes rather than disposal processes. The disposal methods are regularly checked by our experts for optimization possibilities. This enables us to direct waste streams to a higher-quality recycling process.

-

Environmental Management Systems

As part of our ISO 14001 certified environmental management systems, we are striving to implement the processes and measures required by law and to minimize risks at all our production sites. Our activities focus on the protected assets of air, water and soil, for the protection of which we have defined technical and organizational requirements within the framework of company-wide standards. Ensuring an environmentally friendly handling of hazardous substances is particularly relevant for preventing environmental pollution. By 2025, we are aiming for a worldwide rollout of ISO 50001 energy management certification for all our production sites.

Our progress so far

- In 2022 we achieved CO₂-neutrality in production for our sites in Europe on the balance sheet – through among other things the procurement of CO₂-free electricity from solar, wind and hydropower and the procurement of certificates.

- 7,200 kWp we have installed photovoltaic modules in our plants, which can generate around 7,900 MWh of electricity per year.

- 92% of our relevant sites (production plants, development, and test track sites) are ISO 14.001 certified.

Our next steps

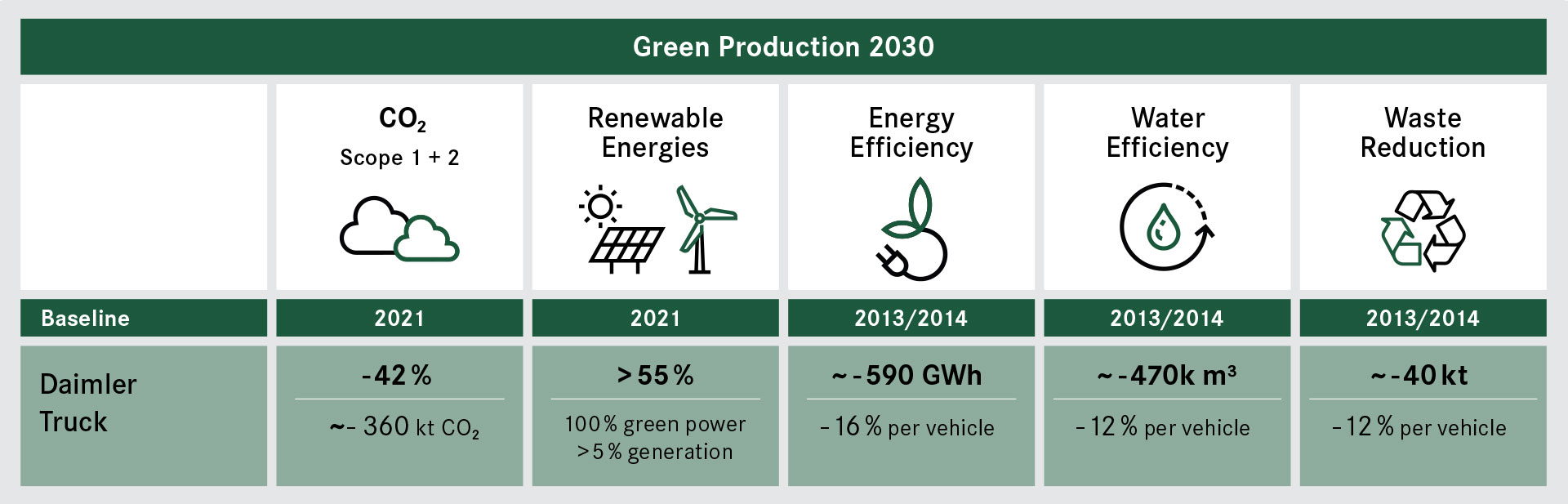

As part of our “Green Production Initiative”, we aim to achieve the following objectives by 2030:

- We aim to reduce production-related CO2-emissions by 42 % compared to the emission levels in 2021.

- At least 55 % of energy is expected to come from renewable energy sources.

- Our goal is to reduce energy consumption by around 590 GWh**.

- We aim to reduce water use by around 470,000 m3**.

- We want to reduce waste by around 40,000 tons**.

** based on the average value for the years 2013 and 2014